Test & Inspection

NDT Leak Testing

How can you make the most of this increasingly precious commodity for your critical quality assurance needs?

Read More

NDT Leak Testing

Leak Testing Meets New Energy Storage Needs

Leak tightness is a major criterion for stable performance of a battery pack over the expected lifetime of an electrical vehicle.

August 5, 2020

NDT Trends

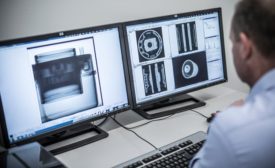

Remote Evaluation of Radiographic Images

Let’s examine the application of remote radiographic evaluation and the subsequent commercial benefits for business.

August 5, 2020

NDT Back 2 Basics

How the Internet of Things and Cloud-Based Apps Are Changing NDT Inspections

It enables new tools that can transform the inspection process.

August 5, 2020

E-Mobility Inspection

With electric vehicles on the rise, so too are the inspection applications.

August 1, 2020

Faster Inspection Reporting

Inspection reports can be completed in less time with the right tools.

August 1, 2020

Sponsored Content

White Paper: Compact 2D/3D Laser scanners with integrated controller reinvigorate profile measurements

August 1, 2020

Pushing the Limits of Precision

As with many critical industries, aerospace requires accuracy on the shop floor.

July 13, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing