NDT

NDT | Eddy Current

Eddy Current Testing in Manufacturing Applications

Eddy current provides a balance of speed, reliability, cost effectiveness, and versatility.

February 8, 2022

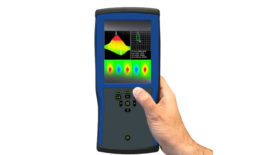

NDT | XRF

How to Measure Metal Coating Thickness Using Handheld X-ray Fluorescence Analyzers

Handheld XRF is an indispensable tool in quality assurance that provides multiple benefits.

February 8, 2022

NDT | LIBS

How to Evaluate Accuracy and Why You Should Calculate the Error Margin of Spectroscopy Measurements

We must be able to estimate the error in a spectroscopy measurement to assure ourselves, and our customers, of the true composition of the material.

February 8, 2022

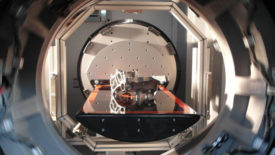

NDT | Computed Tomography

How Nondestructive Testing is Driving Sustainable Quality in the Automotive Sector

NDT techniques are available that are just as quick as destructive methods but also offer a more sustainable use of raw materials.

February 8, 2022

NDT | Computed Tomography

Computed Tomography's Solution to Battery Safety Concerns

A battery is a great example of the value of CT compared to simple radiography.

February 8, 2022

NDT

Quality 101: The Advanced Force Tester

Assuring Material Properties Through Material Testing

February 8, 2022

Quality Headline

ASM, ASTM International Announce Educational Collaboration

December 13, 2021

How Automation Helps to Improve Quality

Automating quality control can look different for every organization.

December 10, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing