NDT

NDT | Material Analysis

Why Complementary Material Analyzers are Essential to Leveraging the Benefits of Quality 4.0

When a manufacturing process is completely automated, it is essential to have the right analyzer for each stage of the process.

August 15, 2021

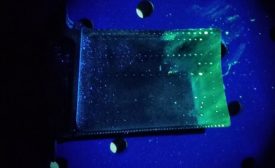

NDT | Back 2 Basics

Liquid Penetrant Audit Preparation

Providing the inspectors with good equipment in the first place can prevent future audit problems.

August 15, 2021

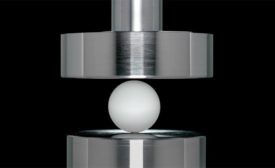

NDT | Compression Testing

Squeezing the Most Out of Compression Testing

The data derived from compression testers can be helpful throughout the life cycle of a product.

August 15, 2021

NDT | Trends

Monitoring Assets with Restricted Access Phased Array

Corrosion is complex, and mitigating and managing it is not a linear process.

August 15, 2021

Aerospace | NDT in Aerospace

NDT in Aerospace: Advancements in NDT Methods

As the Industry will Continue to Grow, so will Advancements in NDT Methods.

July 15, 2021

Aerospace | Back 2 Basics

Leak Test 101: The Basics Rule, No Matter How Much Technology Evolves

These best practices are relevant whether the right leak test for your application is pressure/vacuum decay, mass flow, or tracer gas.

July 15, 2021

Aerospace | NDT in Aerospace

Ensuring Aerospace Component Quality with CT-Data Analysis and Visualization Software

For as long as There Has Been Commercial and MilitaryFlight, Aircraft Compoenent Suppliers Have Been Charged With Providing Dimensional and Process Control-Related Data.

July 8, 2021

Aerospace | NDT AS9102

How to Simplify Your AS9102 First Article Inspection Process

What is First Article Inspection?

July 8, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing