NDT

NDT Leak Testing

Leak tightness is a major criterion for stable performance of a battery pack over the expected lifetime of an electrical vehicle.

Read More

NDT Trends

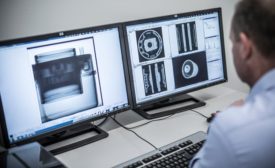

Remote Evaluation of Radiographic Images

Let’s examine the application of remote radiographic evaluation and the subsequent commercial benefits for business.

August 5, 2020

NDT Back 2 Basics

How the Internet of Things and Cloud-Based Apps Are Changing NDT Inspections

It enables new tools that can transform the inspection process.

August 5, 2020

NDT News

NAM Survey: Manufacturers Continue Operating in Support of COVID-19 Response

August 5, 2020

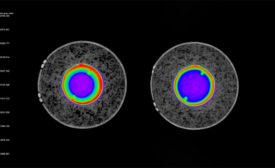

Computed Tomography: Back to Basics

Computed tomography is a powerful nondestructive evaluation (NDE) technique for both 2D and 3D cross-sectional images of an object from X-ray images.

July 1, 2020

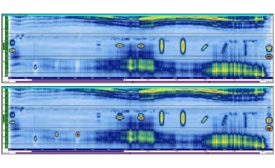

A New Angle on Aerospace FSW Inspections

The most effective inspection method for friction stir weld flaws is phased array ultrasound.

July 1, 2020

Nadcap Nondestructive Testing Special Process Audits: A Perspective

Numerous members of the aerospace industry are involved and provide input.

July 1, 2020

X-Ray and CT Automation Advances Make Aerospace Inspection Easier

How the advances are benefitting aerospace engineers with increased flexibility, improved image quality, better reporting and data storage capabilities.

July 1, 2020

Radiographic Image Interpretation: Doing it Right

The process of radiographic interpretation consists of many variables with the major objective being achieving the highest possible quality level.

June 11, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing