Vision & Sensors

INDUSTRY HEADLINE

A3 Announces Finalists in Automate Launch Pad Startup Competition

March 8, 2017

Emerging Trends in 3D Imaging Applications

3D imaging is here and growing fast.

March 1, 2017

Different Machine Vision Network Interface Options

Choosing the right network interface is an important part of developing successful machine vision applications.

March 1, 2017

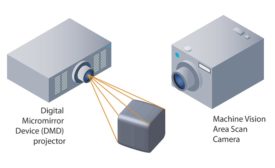

Capturing the Third Dimension for Machine Vision

New technologies now in development may help make 3D more accessible for a larger number of manufacturers.

March 1, 2017

V&S HEADLINE

Princeton Infrared Technologies Announces New Director of Sales and Marketing, Bob Struthers

February 27, 2017

V&S HEADLINE

2016 Breaks Records for North American Robot Orders and Shipments

February 13, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing