Vision & Sensors

The Hybrid Approach

Combining the best of traditional machine vision and deep learning.

January 12, 2021

2D Optical Measurement For 100% Component Inspection

Finding a system to handle 4,000 individual components a day.

January 12, 2021

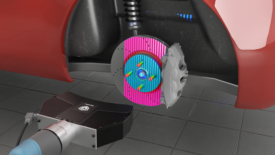

Robots Pave Way For Sustainable Mobility

A significant investment in key technologies ensure that high safety and quality requirements are met.

January 12, 2021

Quality Headline

Verisurf Software Partners With OpenX to Close Skills Gap

December 21, 2020

Vision & Sensors Headline

Teledyne Imaging Concludes Successful Virtual Technology Showcase

December 14, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing