Vision & Sensors

Systems integration is the process of bringing together diverse and disparate components and sub-systems and making them function as a single unified system.

Read More

A Customizable Vision for the Quality Profession

The future of quality inspection is one that will see quality professionals working side-by-side with collaborative robots fitted with easily-swapped vision systems.

September 1, 2020

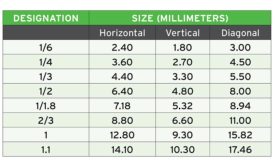

Several Common Image Analysis Software Tools in Machine Vision

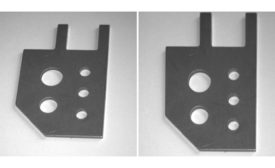

There are many different ways that an image can be distorted.

September 1, 2020

Vision & Sensors Headline

AIA Announces New International Vision Solutions Conference

August 12, 2020

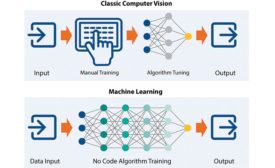

Simplifying AI Deployment for Quality Inspection

Adopting a hybrid approach that marries classic and machine learning techniques for quality inspection can simplify deployment.

June 30, 2020

Machine Vision Frame-by-Frame

Once written off as old tech, the frame grabber has become a necessary, dynamic component of industrial inspection.

June 30, 2020

Vision & Sensors

The Fine Line between Industrial and Collaborative Robots: It’s Smaller than You Think

Knowing how much human-robot collaboration your application needs is the first step towards a successful adoption.

June 27, 2020

Vision & Sensors

Achieving higher levels of quality consciousness with Traceability 4.0

Success in building the factory of the future depends on manufacturers reimagining and broadening their investment in an operational stragety that's been around for decades.

June 25, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing