Vision & Sensors

Vision sensors are an especially great choice for users that are getting started with vision.

Read More

The Resurgence of Vision Guided Robotics

Manufacturers that have dismissed the use of robotics in the past are now taking a fresh look due to advancements in machine vision technology.

July 1, 2018

Matching Human Visual Perception

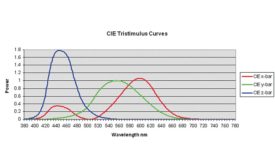

Learn more about the advantages and applications of CCD imaging for light and color measurement.

July 1, 2018

INDUSTRY HEADLINE

Automation Trends At IMTS 2018: Cobots, Cameras, Careers, Mobile Robots, IIoT, AI And More

June 25, 2018

V&S HEADLINE

North American Machine Vision Market Grows 19% in First Quarter of 2018, Sets New Records

June 19, 2018

INDUSTRY HEADLINE

PTC and Rockwell Automation Announce Strategic Partnership

June 11, 2018

INDUSTRY HEADLINE

Universal Robots CTO Wins Engelberger Award, the “Nobel Prize” of Robotics

May 30, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing