Vision & Sensors

The goal is to create smart cameras that can do it all. How do we get there?

Read More

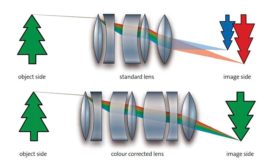

Vision & Sensors Lens Selection Guide, Part 1

Understand the differences between the most common types of lenses used in machine vision.

April 30, 2018

Embedded Vision Puts Full Power in Compact Footprint

Developers are working to drive out cost and reduce system size while offering enhanced flexibility.

April 30, 2018

Optics for High Accuracy Machine Vision

The best lens for a machine vision application is one that’s specifically selected for the sensor used in the camera.

April 30, 2018

Vision Sensors Set New Standard for Pass/Fail Inspections

By combining powerful vision tools, simple setup and a modular design, vision sensors set new standards for value, ease of use and flexibility.

April 30, 2018

Vision System Assures Glass Act at California Shop

With the vision system in place, PG&O has substantially ramped up its inspection productivity.

April 30, 2018

INDUSTRY HEADLINE

MSE Manufacturing Event Continues to Bolster Offerings and Lineup

April 16, 2018

V&S HEADLINE

Radiant Vision Systems Honored by Vision Systems Design 2018 Innovators Awards Program

April 12, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing