Vision & Sensors

Maximizing Computer Vision Image Quality with Automated Active Sensor Alignment

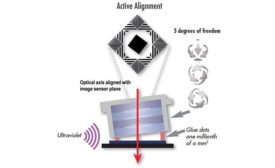

Machine vision applications are seeing a shift to high quality, high dynamic range sensors.

December 1, 2017

Modern UI Design for the Industrial Internet of Things

The move to smart, embedded devices running web technology is capable of fully realizing the potential of the IIoT.

December 1, 2017

V&S HEADLINE

AIA Board of Directors Election Nomination Deadline is Dec. 15

November 29, 2017

V&S HEADLINE

Leonardo DRS Selects Sierra-Olympic as Master Distributor of Uncooled Thermal Camera Cores in U.S.

October 20, 2017

V&S HEADLINE

MVTec Names Christoph Wagner as Embedded Vision Product Manager

October 10, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing