Featured on Home Page

Software & Analysis

From addressing labor shortages, to reducing human error, the future looks bright for quality inspection software.

Read More

Test & Inspection

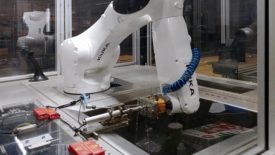

Quality Automation: The Role Robotics and Sensors Play in Quality Control and Production

Manufacturers looking to improve their production process efficiency and effectiveness should look closely at Quality Automation.

May 8, 2023

Vision & Sensors | Machine Vision 101

Image Processing for Machine Vision – How Did We Get Here?

Machine Learning (ML) has been part of machine vision image processing almost from the beginning.

May 4, 2023

Vision & Sensors | Vision

40+ Years of Vision Guided Robotics

VGR is one of the largest growing sectors in both the robotics and machine vision market.

May 3, 2023

Vision & Sensors | Deep Learning

Can Deep Learning Improve My Manufacturing Process?

By applying DL with a Data-Centric Approach, Users Can Streamline Even the Most Challenging Manufacturing Steps with Fast, Accurate Automated Inspection.

May 2, 2023

Inaugural Quality Rookie of the Year Winner

2023 Quality Rookie of the Year: Jared Curtis, Time for a Challenge

Our Rookie of the Year had twenty years of experience when he decided to switch careers.

May 1, 2023

Quality in Automation | Quality 4.0

Time for Quality 4.0

Changes in industry are taking place now.

April 20, 2023

Quality in Automation | Robotics

Automated Robotics Are Just Getting Started

These machines are only gaining favor post pandemic.

April 19, 2023

Speaking of Quality | Jim Spichiger

Accomplishments Build on One Another

Professional credentials led me to push myself further.

April 18, 2023

Column | Darryl Seland

From the Editor: Iterations

From manufacturing to personal growth.

April 17, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing