Featured on Home Page

Test & Inspection

Recently, researchers have shown correlation between particle hardness and cycle performance.

Read More

Quality Professional of the Year Winner

2023 Quality Professional of the Year: Saso Krstovski, A Career in Quality

Meet Saso Krstovski, technical expert, mentor, scholar and quality problem-solver.

March 31, 2023

Measurement

How to Measure the Intricate Components of Electrical Connectors

Quality assurance is critical for manufacturing electrical connectors.

March 30, 2023

Quality 101

Learns from ISO 9001:2015

Having conducted well over 700 audits, I've noticed some patterns.

March 29, 2023

Software & Analysis

Quality Software: Core Qualities to Build Specialist Software Tools in QC Metrology

Manual operations cannot fully meet the challenges of a competitive and increasingly digitized industry.

March 28, 2023

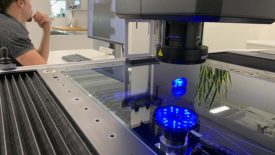

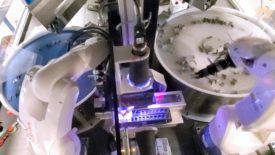

Vision & Sensors | Machine Vision 101

System Integration: Consolidating Vision Systems into the Manufacturing Process

Complex machine vision inspection systems have become a key component of the manufacturing process.

March 17, 2023

Vision & Sensors | Cameras

The Changing Face of Smart Cameras in Machine Vision

Beyond the growth in applications brought about by improvements in CMOS sensor technology, another significant trend is the increase in applications that extend beyond the visible spectrum.

March 16, 2023

Speaking of Quality | Collin Sutt

From Firefighter to Proactive Problem Solver

Making this kind of shift can be a monumental task, requiring a multifaceted approach.

March 15, 2023

Column | Darryl Seland

From the Editor: Riddle Me This

Aristotle and self-drive cars.

March 14, 2023

Software & Analysis

Make A Quality Part On Time Every Time With ERP Software

With modern ERP software, scrapping non-conforming parts can and should happen in real time.

March 10, 2023

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing