Featured on Home Page

Vision & Sensors | Lenses

The wavelengths used in any machine vision application have significant implications in choosing the ost appropriate lens.

Read More

Vision & Sensors | Robotics

The Rise of Smarter Robots

Using a high-quality 3D camera, the robot can locate the part, regardless of orientation, and provide pick coordinates to the robot.

March 1, 2022

Software & Analysis

How ERP Software Impacts Quality

The right solution enables businesses to track and measure the total cost of quality.

March 1, 2022

Case Study

How A Custom Crusher Used Precise Motion Data To Open New Manufacturing Possibilities

The problem wasn't whether the client could make the parts; it was whether the client could test samples in a rapid, cost-efficient, productive way.

February 15, 2022

Test & Inspection

The Shrinking Pixel

What motivates smaller pixels? It's mainly cost, which is directly tied to image sensor size.

February 15, 2022

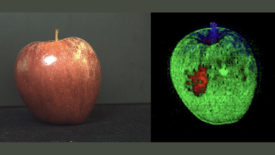

Test & Inspection

How Collaborative Is Your Manufacturing Application?

The design and operation of the manufacturing application will determine how and how often the human and robot will collaborate.

February 15, 2022

NDT | Eddy Current

Eddy Current Testing in Manufacturing Applications

Eddy current provides a balance of speed, reliability, cost effectiveness, and versatility.

February 8, 2022

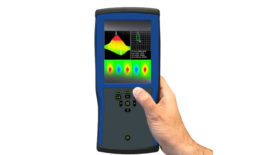

NDT | XRF

How to Measure Metal Coating Thickness Using Handheld X-ray Fluorescence Analyzers

Handheld XRF is an indispensable tool in quality assurance that provides multiple benefits.

February 8, 2022

NDT | LIBS

How to Evaluate Accuracy and Why You Should Calculate the Error Margin of Spectroscopy Measurements

We must be able to estimate the error in a spectroscopy measurement to assure ourselves, and our customers, of the true composition of the material.

February 8, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing