Featured on Home Page

Vision & Sensors | Trends

As business needs grow and transform over time, suppliers continue pushing machine vision technology forward.

Read More

Vision & Sensors | Collaborative Robots

Collaborative Automation Delivers Quality Boost

Ease of use is one of the main attractions of collaborative automation.

December 8, 2022

Vision & Sensors | Automation

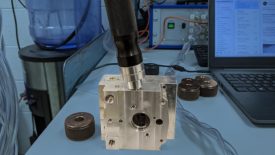

Metrology Automation Finally Arrives

The smart start to metrology.

December 7, 2022

Management

The Enduring Importance Of Quality Standards

Some benefits of quality standards are obvious, while others don't get enough fanfare. The pandemic may have impacted how these standards are implemented.

December 2, 2022

Software & Analysis

6 Trends That Make a Modern Laboratory Effective

The time and effort required to get from raw data to decision making can be the difference between leading or lagging behind your competition.

December 1, 2022

Test & Inspection

The Most Common Styli Used Today

Let's discuss the most common styli used today.

November 30, 2022

Speaking of Quality | Tracy Owens

Why It's Important to Read Speaker Reviews

Reading the reviews of my own presentations is always a moment of excited hesitation.

November 25, 2022

Face of Quality | Jim L. Smith

Workplace Culture Influences Employee Attitudes

Management Influences Attitude

November 24, 2022

Quality 101

Air Gaging Basics: The 4 W’s

What, who, why, and where of air gaging.

November 23, 2022

ISO 9001 Standards

Why ISO 9001 Still Matters

There’s no one single right way to apply the standard – as long as there is conformance to requirements.

November 17, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing