Articles by Darryl Seland

Automobiles and Automation

From the wheel and horse to the push of a button.

January 15, 2020

Post-Process Monitoring, Part 2

Robotic automation and post-process monitoring

December 6, 2019

Manufacturers Show Their ‘Metal’ Using the Imaging Power of Digital Microscopes

Improving the quality of metal-based products.

December 6, 2019

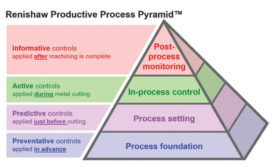

Post-Process Monitoring

Its relationship to additive manufacturing, automation, and more.

November 25, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing