Home » Keywords: » USB 3.0

Items Tagged with 'USB 3.0'

ARTICLES

Vision & Sensors | Interfaces

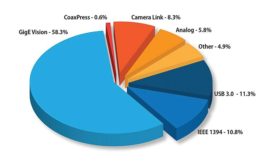

This new wave of interface design choices is significantly influenced by the electronics, mobile, and personal computing markets.

Read More

Applying the CoaXPress Interface in Multi-Camera Machine Vision Systems

Multiple camera systems have been a fixture in machine vision for decades. What is new is the use of CXP.

January 1, 2020

Connected in Quality

Portable optical inspection system for composite materials with USB 3.0 camera provides reproducible measurement results including documentation.

May 15, 2019

USB Brings Cost and Connectivity Advantages to Imaging

USB is the most prevalent method to connect computers and peripheral devices. Taking a survey of my desk there are a multitude of devices—a smartphone, headphones, a camera, mouse and keyboard—that rely on a USB connection.

March 1, 2018

The Future of Machine Vision Standards

Because of the large scope of machine vision, there can be no true winner of this battle of standards.

July 1, 2017

Machine Vision goes Embedded Vision

In this new embedded setting the individual components are combined and become one device, so machine vision becomes embedded vision.

September 1, 2016

The Human Side of Machine Vision

VISION STANDARDS ARE ADVANCING THE DESIGN OF NEW MACHINE VISION TECHNOLOGIES WHILE STILL ADDRESSING THE HUMAN NEED FOR SIMPLE TO USE SYSTEMS.

December 16, 2015

Zooming in: CCD Cameras

THE SKINNY ON CCD VS. CMOS CAMERAS AND THE FUTURE OF HIGH-QUALITY IMAGING.

December 16, 2015

3-D Imaging: Past, Present, and Future

EXPERTS FROM CHROMASENS, BITFLOW DESCRIBE THE STATE OF 3-D IMAGING IN MACHINE VISION.

September 8, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing