Home » Keywords: » efficiency

Items Tagged with 'efficiency'

ARTICLES

How Scalable is your Software?

Quality methods call for quality software that will be embraced by all.

August 26, 2020

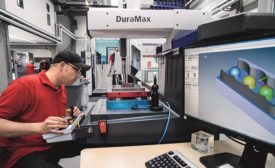

Fully Leveraging Machine Uptime

Offset measurements away from the machine tool boost manufacturing efficiency.

November 5, 2019

INDUSTRY HEADLINE

ASQ to Offer Lean Six Sigma Black Belt, Green Belt Courses

July 31, 2014

EVENTS

Webinar

2/18/25 to 2/18/26

Contact: Meg K.

Minimize Poor Quality Costs: How to Boost Your Brand and Business

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing