Home » Keywords: » 3D

Items Tagged with '3D'

ARTICLES

Vision & Sensors | Collaborative Robots

Ease of use is one of the main attractions of collaborative automation.

Read More

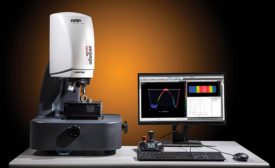

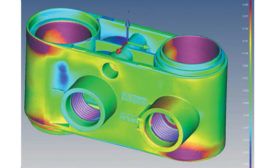

Why model-based Measurement Helps Manufacturers Improve Quality

Improvements in CMM equipment and developments in model-based software solutions have also helped make the technology more accessible.

March 23, 2022

TEST & INSPECTION

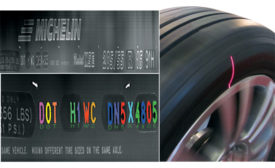

Changing Face of Additive Manufacturing Inspection

As Manufacturers Embrace Increasingly Complex Materials and Processes, Their Inspection Methods Evolve with Them.

June 1, 2021

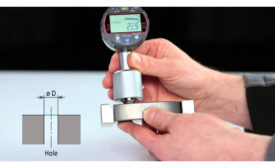

Edge Break Analysis for 3D Optical Metrology

Handheld 3D metrology that uses edge break analysis software can bring precise edge break measurements to the shop floor.

August 3, 2020

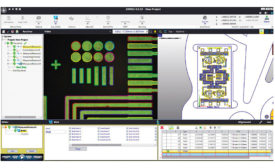

Certified Inspection with CT Scanning

The most accurate CT scanning systems are built like a CMM with an X-ray probe.

July 1, 2016

Measurement

The Shape of Things to Come: A Look at the New ISO Form Standards

These standards may have a significant impact on how some companies specify, measure and manufacture parts.

September 3, 2013

EVENTS

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing