Home » Keywords: » smart sensor

Items Tagged with 'smart sensor'

ARTICLES

The State of Sensors in the Industrial IoT

Better quality is possible with IO-Link and machine learning.

August 8, 2019

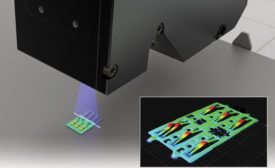

Advancing Factory Automation with Smart 3D Imaging and Inspection

The Industrial Internet of Things and the Move Toward Smart Technologies

May 8, 2019

Designing a Better Sensor for Small Parts Inspection

Smart technology advancements are at the heart of today's movement toward better sensor design.

March 1, 2019

Trends in Sensor Technology for Quality Control

Advancements in laser measurement technology and the adoption of IO-Link communication are making complex inspections easier, more reliable, and more cost-effective.

March 8, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing