Trends in Sensor Technology for Quality Control

Advancements in laser measurement technology and the adoption of IO-Link communication are making complex inspections easier, more reliable, and more cost-effective.

Laser measurement is ideal for error-proofing small height differences. In this example, the Q4X laser distance sensor verifies the presence of a small rubber washer on an engine block.

Fast, reliable error-proofing is essential to ensuring consistent throughput without sacrificing quality. Manual quality inspections are often tedious and prone to error, and complicated vision systems can be expensive and time-consuming to implement. Meanwhile, sensor solutions often require multiple sensors for more complex inspections. However, this is no longer always the case.

Thanks to advancements in laser measurement technology, sensors can now measure more challenging targets (including clear, reflective, and low contrast targets) and can handle multiple inspection tasks with one sensor. In addition, with IO-Link communication, it is becoming easier to track sensor performance, identify trends in inspection results, and even predict when maintenance is needed so that simple problems like a dirty lens can be fixed prior to sensor failure.

This article explains how advancements in laser measurement technology and the adoption of IO-Link communication are making complex inspections easier, more reliable, and more cost-effective.

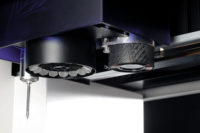

Laser measurement is also ideal for low contrast applications. In this example, the Q4X verifies dark targets on a dark background.

Dual Mode Sensing: Distance Plus Light Intensity

Traditionally, laser measurement sensors only measured distance, most commonly using either laser triangulation or time-of-flight technology. Now, some laser measurement sensors can measure both distance and light intensity (which we will call dual mode).

What this means is that the sensor can detect not only when the target is present within a certain distance but also when it returns a certain amount of light to the receiver. While the CMOS imager (the underlying technology behind dual mode) is not new, sensor manufacturers are now using the technology to unlock a sensor’s ability to provide multiple pieces of information and function as both a distance and contrast sensor all in one.

Dual mode sensing (detecting both distance and light intensity) allows laser measurement sensors to detect more challenging targets, including clear and reflective objects.

More Inspections with Fewer Devices

One way that smart sensors with dual mode save costs is by allowing users to inspect multiple conditions with a single device. In a recent application in the electronics manufacturing industry, a single laser distance sensor with dual mode was used for error-proofing integrated circuit chips in pocket tape.

Error-proofing for this application required determining the following conditions:

Is a circuit chip present? This is determined by distance. If no chip is present, the distance between the sensor and the target will be too great.

Is more than one chip present in each pocket? This is also determined by distance. If a second chip is stacked on top of the first chip, the distance between the sensor and the target will be too small.

Is the chip right side up? This is determined by contrast, since one side of the chip is a darker color than the other. The intensity of light returning to the sensor’s receiver is lower if the dark side of the chip is facing up.

Traditionally, an application like this would require at least two sensors: one to detect changes in distance, and one to detect contrast. With dual mode, a single laser distance sensor can accurately detect all three conditions (missing, duplicate, or right side down chips) with one device.

IO-Link communication makes sensors more powerful and makes device data available for the Industrial Internet of Things (IIoT). This diagram shows IO-Link devices within an IO-Link system.

Reliable Measurement and Detection of Challenging Targets

In addition to enabling more inspections with one device, dual mode sensors can also verify the presence of targets that other laser- and LED- based sensors typically struggle to detect, including clear and reflective targets. Because they measure distance, laser sensors are also ideal for reliable inspection in low contrast applications where other sensors struggle (for example, verifying tread height on tires in the automotive industry). Smart sensors can also recognize if very little light is returning to the receiver—for example, when detecting dark objects. The sensor will automatically adjust its exposure settings for additional gain and a stronger signal.

Cost Savings

Using smarter, more powerful sensors allows manufacturers to solve more applications with fewer devices, reducing upfront costs and long-term costs of maintaining additional sensors. With these multifunctional devices, manufacturers can standardize on fewer sensor models, which also reduces inventory costs and simplifies operator training.

IO-Link Communication

Another important technology that can help save time and costs in quality control applications is IO-Link communication. IO-Link allows for the bi-directional exchange of data from sensors that support IO-Link and are connected to a master. With IO-Link communication, sensor data can be accessed in real-time and logged for long-term analysis. This allows quality control processes to be monitored in real-time and optimized over time based on stored data. Key benefits include real-time remote monitoring and diagnostics, predictive maintenance, and auto-device replacement.

Real-Time Remote Monitoring and Diagnostics

IO-Link provides users with visibility into errors and health status from each sensor. This means that users can see not only what the sensor is doing but also how well it is performing. In addition, real-time diagnostics allow users to easily identify when a sensor is malfunctioning and diagnose the problem without shutting down the line or machine. For example, with IO-Link users can quickly identify exactly why an inspection condition failed, which helps resolve problems faster. Inspection pass/fail rates can be tracked over time to determine the best course of action.

Furthermore, the discovery function with IO-Link indicates which sensor needs attention, especially where many sensors are grouped together. When there are multiple sensors in a confined space, it can be difficult to determine which sensor requires cleaning. The discovery function allows the problematic sensor to flash, making it easy to identify and address the issue quickly, reducing unplanned downtime.

Predictive Maintenance

IO-Link communication can also be used for predictive maintenance. For example, decreases in a sensor’s excess gain due to the accumulation of debris can impact sensing function over time. With IO-Link, operators can be alerted in advance so that the sensor can be cleaned before it fails. Furthermore, with IO-Link, users can also track sensor runtime to estimate when a sensor will require maintenance or replacement so that issues can be addressed during scheduled maintenance.

Easy Auto-Device Replacement

When a device does require replacement, IO-Link’s data storage capability allows for automated parameter reassignment (this functionality is also known as Auto-Device Replacement or ADR). Users can import existing sensor parameter values into a replacement sensor for seamless replacement, getting the new device up and running as quickly as possible.

Conclusion

Overall, adopting smarter sensors with dual mode and IO-Link communication can help solve more error-proofing applications with greater reliability and fewer devices. Choosing smart sensors also allows plant managers to optimize their quality inspection processes based on data from the devices themselves.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!