Home » phased array

Articles Tagged with ''phased array''

NDT | Back2Basics

These technologies enhance the accuracy, speed, and thoroughness of flaw detection in critical components, contributing to improved safety and reliability in aerospace operations.

Read More

How to Choose the Right PAUT Probe for Every Inspection

A Comprehensive Guide for Industry Professionals

September 12, 2024

NDT | Back2Basics

Advancements in Ultrasonic Testing: Unveiling the Tidal Force of Plane Wave Imaging on Nondestructive Testing Techniques

Plane wave imaging represents a groundbreaking approach within the realm of phased array ultrasonic testing.

May 16, 2024

NDT | Ultrasonics

Smart Inspection: Latest developments and novel approaches in industrial ultrasonic testing

Compact design and automation are important aspects in meeting the inspection requirements of today and the future.

March 1, 2024

Test & Inspection

Phased array ultrasonic testing (PAUT)

Phased array ultrasonic inspection has become an indispensable tool in the aerospace industry, contributing to the safety and reliability of aircraft components.

December 31, 2023

NDT | Phased Array

Phased Array Ultrasound (PAUT) vs Phase Coherence Imaging (PCI) for Pipeline Inspection

One of PCI’s main strengths is detecting cracks that are vertical to the surface of the component.

October 3, 2023

NDT | Phased Array

Phased Array Ultrasonic Testing

Inspection reliability continues to improve thanks to the development of new imaging techniques like the total focusing method.

August 11, 2023

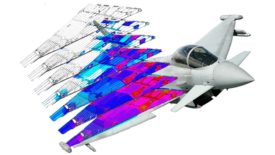

Aerospace | Phased Array

Phased Array Ultrasonic Testing: A Tutorial

While PAUT is becoming a popular approach for nondestructive inspections, it is important that users understand this technology, its limitations and how it should be applied.

July 11, 2023

NDT | Standards

The Evolution of Ultrasonic Testing (UT) from Conventional UT to Total Focusing Method

As technology continues to advance, ultrasonic testing advances too.

November 11, 2022

NDT | Phased Array

The Hilbert Transform’s Role in Transforming TFM

With improvements to TFG technology, more users of conventional phased array are showing interest in incorporating the method into their procedures.

August 8, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing

.jpg?height=168&t=1659976174&width=275)