Home » machine vision

Articles Tagged with ''machine vision''

Beginning with the AIS's camera link standard, the industrial camera portion of the imaging system was standardized.

Read More

How Machine Vision Cables Impact Machine Vision Performance

Choosing high quality cables is your best approach for long-term productivity and consistent imaging data.

July 1, 2019

Machine Vision Lens Performance

A number of factors are important in lens design, including lens resolution, spatial distortion, and uniformity of illumination.

May 1, 2019

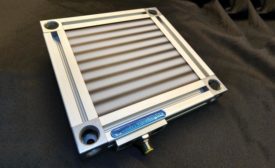

Patterned Area Lighting Simplifies Imaging of Reflective and Transparent Surfaces

The goal of PAL lighting is to enhance diffiult-to-image flaws so machine vision software can evaluate them.

March 1, 2019

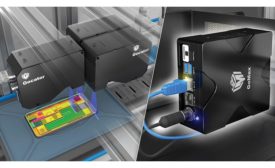

Q&A: 3D Smart Sensors, Deep Learning, and The Future of Automated Quality Control

The CEO of LMI Technologies describes how 3D sensors are integral to a new era of quality.

March 1, 2019

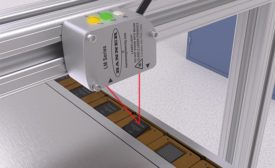

How to Choose a Precision Measurement Sensor: Key Considerations

In precise part inspections, a reliable solution is a must.

March 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing