Home » machine vision

Articles Tagged with ''machine vision''

Vision & Sensors | Interfaces

The Newly Developed CoaXPress 2.0 Standard will Increase the Performance of Your Vision System With Twice the Data Rate.

Read More

Vision & Sensors | Machine Vision 101

Image Analysis 101: The Role of Artificial Intelligence

A Growing Number of Manufacturers are Using Deep Learning Tools, a Subset of Artificial Intelligence, to Reduce Waste and Improve production. But, Experts Say, Some of it is Just Hype.

July 6, 2021

Vision & Sensors | Trends

Why is Manufacturing Flexibility Important?

The Need for This Flexibility is Likely to Continue Accelerating.

July 1, 2021

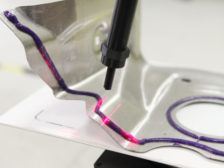

Inspection

Quality and Process Control for the Dispensing Process

For Many Applications, Good Robot Programming is an Art.

May 18, 2021

Sponsored Content

White Paper: Machine Vision, AI & the Cloud are Creating the Scalable, Autonomous Inspection System of the Future

April 21, 2021

VISION GUIDED ROBOTICS

Best Practices for Implementing Vision Guided Robotics

An important first step in any application is a thorough project evaluation prior to system design and implementation.

April 8, 2021

VISION & SENSORS - MACHINE VISION 101

Engineered Lighting: Part 2 of 3

Learn how to choose a light source to take advantage of the characteristics that create contrast.

March 9, 2021

VISION & SENSORS - LENSES

Protecting Lenses

Imaging systems have specific design requirements to maintain performance without degrading over time.

March 9, 2021

VISION & SENSORS - SENSOR TRENDS

Event-Based Vision: Taking a Cue From Biology

We can replicate the efficiency of how our eyes work with a new form of vision capture called event-based vision.

March 9, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing