Home » machine vision

Articles Tagged with ''machine vision''

Vision & Sensors | Vision

The move to Industry 4.0 requires better connectivity to enable data trasnfer and sharing between all components within the factory structure.

Read More

Vision & Sensors | Lighting

Three Challenges In Machine Vision Lighting Today And How To Solve Them

With increased speeds, dynamic production lines, and advanced inspection processes, smart automated lightng is driving machine vision solutions.

May 1, 2022

Vision & Sensors | Trends

The Place for Deep Learning in Industrial Machine Vision

Deep learning is an "add on" to traditional machine vision. It does not eliminate the ability to handle a range of tasks using traditional tools.

May 1, 2022

Vision & Sensors | Machine Vision 101

Advancements In Telecentric Technology

As telecentric lenses become more compact, the overall footprint of vision systems will follow.

March 2, 2022

Vision & Sensors | Lenses

Optimizing Machine Vision Lenses For Different Wavelengths

The wavelengths used in any machine vision application have significant implications in choosing the ost appropriate lens.

March 1, 2022

Vision & Sensors | Robotics

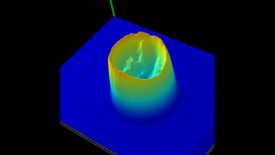

The Rise of Smarter Robots

Using a high-quality 3D camera, the robot can locate the part, regardless of orientation, and provide pick coordinates to the robot.

March 1, 2022

Vision & Sensors | Trends

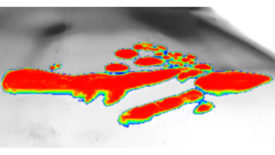

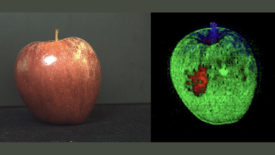

Advanced Imaging And Deep Learning Technologies Execute Critical Packaging Inspection

While machine vision applications have been highly successful for decades using "analytical" vision tools, deep learning is able to successfully solve very complex classification and object detection problems with ease.

March 1, 2022

Test & Inspection

How AI and Machine Vision Intersect

No matter how you slice it, machine vision has become more capable.

February 1, 2022

Vision & Sensors

Vision & Sensors 101: Machine Vision System Integration

Success with vision system integration requires starting right.

January 1, 2022

Vision & Sensors | Automation

Bringing AI to Visual Inspection

Adding automated decision-support for human operators helps speed visual inspection rates and improve product quality.

January 1, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing