Home » metrology

Articles Tagged with ''metrology''

From the Editor | Darryl Seland

Software & Analysis

Manual Data Entry And Its Effects On Quality

Let's look at the scary truth behind manual data entry as it relates to the calibration process.

February 1, 2022

Test & Inspection

How AI and Machine Vision Intersect

No matter how you slice it, machine vision has become more capable.

February 1, 2022

Management

2022 Quality Leadership Ranking: When the Going Gets Tough

Leading manufacturers know the importance of continuous improvement.

February 1, 2022

Measurement

Turning GD&T From Grim, Depressing & Troublesome Into Something Grand, Delightful & Tantalizing

For the sake of industries around the world, it is time to make GD&T much easier to use, and much easier to use correctly.

February 1, 2022

Speaking of Quality | Jim Spichiger

ASQ Member Leaders are NICER

Why do these member leaders dedicate their precious personal time to serve?

January 15, 2022

Column | Jim L. Smith

Face of Quality: KPI Fundamentals

Focusing on the right things is the key to success.

January 15, 2022

Column | Darryl Seland

From the Editor: Environmental Influences

Accelerating evoution, delivery apps, and handicapping.

January 15, 2022

Software & Analysis

Using Simple Linear Regression For Instrument Calibration?

Learn why orthogonal regression is a better approach.

January 8, 2022

Quality 101

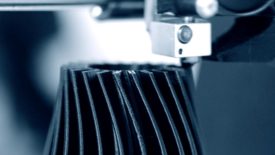

Quality in Additive Manufacturing

To facilitate widespread adoption of AM, it will be necessary for material property data to be shared among the design community at large instead by being held by a few large companies.

January 8, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing