Home » metrology

Articles Tagged with ''metrology''

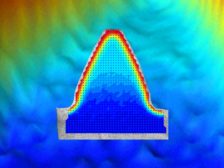

NDT | Ultrasonics

Inspection plays a critical role during all phases of product development and implementation, making UT methods an enabling technology for new AM applications.

Read More

NDT | Computed Tomography

Industrial CT: 3D Inspection and Metrology for 3D Printing

CT inspection of the final part can check that the manufactured part exactly matches the initial 3D design, providing dimensional analysis and metrology of all critical internal dimensions.

October 15, 2021

Column | Darryl Seland

From the Editor: Serendipity, A Meaningful Connection?

October 8, 2021

Column | Jim Spichiger

Speaking of Quality: Code of Ethics

My moral compass has guided me well.

October 8, 2021

Software & Analysis

Gaging Software’s Changing Role

As manufacturers become leaner and integrate metrology in innovative ways, openness and interoperability are paramount.

October 8, 2021

Column | Hill Cox

Other Dimensions: Settling Measurement Disputes

Not all parties to a dispute understand the importance of uncertainty budgets.

October 8, 2021

Column | Jim L. Smith

Face of Quality: Productive Failures

Failure can provide the seeds for success.

October 8, 2021

Test & Inspection

Digital Technologies in Hardness Testing

Modern computer control of hardness testers has advanced far beyond making a single line of indents.

October 1, 2021

Management

Robots Get the Job Done

Mobile robots are an increasingly important part of modern manufacturing.

October 1, 2021

Measurement

Simplifying Metrology System Selection for Medical Applications

Tips for choosing the right vision system.

October 1, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing