Home » nondestructive testing

Articles Tagged with ''nondestructive testing''

A midair engine failure in April puts nondestructive inspections to the test

Read More

Nondestructive Testing Training

Having spent years in the NDT field, I can attest to the importance of a quality NDT training curriculum.

June 8, 2018

Nondestructive Compression Force Testing: What, Why, and How

Nondestructive compression force testing helps quality control professionals assess and ensure product quality.

June 1, 2018

Achieving Consistency and Reliability in Additive Manufacturing

How to create and maintain a quality assurance process.

April 16, 2018

NDT HEADLINE

IMechE Appoints New Head of NDT and Corrosion Inspection Training

March 19, 2018

Short Range Guided Wave Ultrasonic Testing

Make inspections more accurate.

November 13, 2017

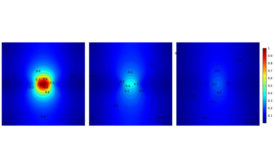

Overcoming the Adverse Effects of Galvanized Steel Weather Jackets

There are several ways of mitigating the effects of galvanized steel on pulsed eddy current inspections.

Marco Michele Sisto

Vincent Demers-Carpentier

Maxime Rochette

Marie-Eve Myrand-Lapierre

Andreanne Potvin

Florian Hardy

October 17, 2017

Faster, Better NDT: The Advantages of Eddy Current Arrays

Multi-coil arrays take eddy current technology many steps further.

August 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing