Home » CMMs

Articles Tagged with ''CMMs''

Confocal white light provides an alternative to traditional laser scanning, allowing for non-contact measurement of shiny and translucent parts.

Read More

New Heights in Height Gages

Today’s multipurpose height gages can perform with near-CMM capabilities.

March 8, 2018

The Rise of Multisensor Measurement

Multisensor CMMs can measure 2D and 3D parts interchangeably, giving manufacturers a competitive edge.

March 1, 2018

CMMs Offer Multiple Applications for the Shop Floor

Once limited to the lab, CMMs are finding a home in harsh manufacturing environments.

February 1, 2018

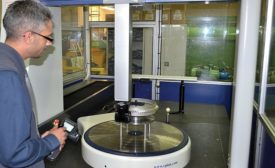

Accurate and Repeatable Measurement

Using a rotary table on a CMM will improve process efficiency and productivity by reducing setup and process times.

October 24, 2017

Understanding the Metrology Language for X-ray Computed Tomography

When compared to CMMs, CT as a technique applied for industrial dimensional metrology is relatively new.

October 17, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing