Home » CMMs

Articles Tagged with ''CMMs''

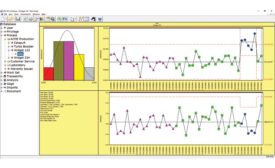

When disruptions are detected, it’s critical that operators have the tools available to quickly diagnose and correct the issues.

Read More

Faster, High Tech Machines Demand Enhanced Safety Precautions

Operators, engineers, programmers and maintenance personnel should adhere to any and all safeguarding procedures put in place.

November 1, 2018

Calibrating Surface Gages for Success

The measurement of surface finish has come a long way in the past 70 years.

October 15, 2018

Computed Tomography: Optimizing Large Quantity Automated Measurements

Learn more about automated measurement techniques for large quantity screening applications.

October 8, 2018

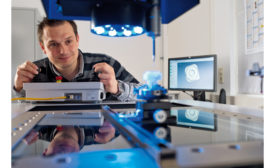

Choosing the Right 3D Scanner

A quality engineer describes how he picks the right tool for the job.

October 1, 2018

Benefits of Multi-Sensor CMMs by Industry

Aerospace, automotive, and medical device OEMs, take note.

June 28, 2018

What is the Value to Your Company of a Leaner, More Productive Inspection Process?

You may be surprised!

June 15, 2018

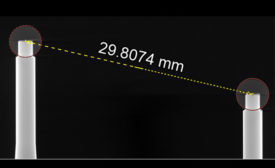

Precision Manufacturing

Leading edge metrology systems help ensure component quality.

June 15, 2018

Using CMMs for Surface Finish Measurement

Advancements in motors and sensors improve CMM surface measurement capabilities.

June 15, 2018

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing