Home » 3D scanning

Articles Tagged with ''3D scanning''

Measurement

When are non-contact structured light 3D scanners better suited than touch CMMs?

Read More

Quality Headline

"Industrial Quality Solutions" Signifies More than Just a Name Change for Zeiss

June 28, 2022

Quality Control With 3D Scanning

3D scanners are quick, accurate and record mass amounts of geometry, making them less laborious and more flexible than basic metrology tools.

January 3, 2022

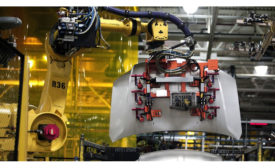

The Benefits of Automation

The five reasons to consider, and have been considered for decades, about automation.

December 10, 2021

How 3D Scanning Solution Boost Quality Gains and Productivity

The key to being successful with automated measuring solutions is to simplify the deployment.

November 9, 2021

Why In-line and At-Line Metrology Solutions Are the Next Step in Automated Quality

Manufacturers who want to completely automate quality control must rethink how to conduct quality in the manufacturing environment.

October 11, 2021

Sponsored Content

White Paper: Compact 2D/3D Laser scanners with integrated controller reinvigorate profile measurements

August 1, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing