Home » 3D scanning

Articles Tagged with ''3D scanning''

First Article Inspection with 3D Scanning

A growing number of companies are including this technology in their first article inspection procedures.

April 1, 2017

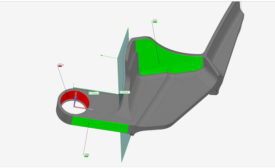

Reverse Engineering: What’s it all about?

There are several scenarios in which reverse engineering is important for modern manufacturers.

March 1, 2017

Boldly Touting Multisensor Value

The value proposition for choosing a multisensor measurement system, compared to a single sensor machine, is productivity and cost savings.

January 3, 2017

INDUSTRY HEADLINE

GOM Launches International Student Competition on 3D Scanning

November 30, 2016

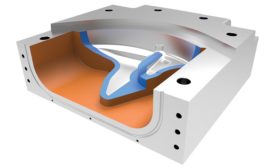

Reverse Engineering Continues to Expand its Role in Industry

Reverse engineering parts and systems enable aircraft to keep flying or machines to keep running.

October 1, 2016

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing