Home » Gage R&R

Articles Tagged with ''Gage R&R''

Measurement system analysis can help you improve the quality of your products.

Read More

Accurate and Repeatable Measurement

Using a rotary table on a CMM will improve process efficiency and productivity by reducing setup and process times.

October 24, 2017

How Not to Fear the Gage R of Your Leak Test

Turn Gage R into a tool for continuous quality improvement.

October 10, 2017

Is Your Measurement System Adequate?

If you can’t trust your measurement system, then you can’t trust the data it produces.

August 1, 2017

Get to Know the Height Gage

The accuracy gets a boost when height gages with repeatable measuring force are introduced.

June 1, 2017

Standard Gage or Custom? How to Analyze Your Gaging Requirements

How to analyze your gaging requirements. Learn how to specify the gaging solution that provides the best results.

May 1, 2017

Gage Repeatability and Reliability: Ensuring Accurate Test Results for Measurement Systems

When designing a GR&R study it is important to select a range of materials that is representative of what the system will be used for.

November 1, 2016

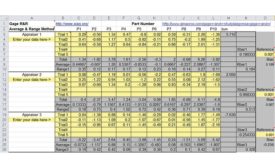

Gage R&R: The Key to Reducing Measurement Variation

A critical part of the journey toward reducing variation is developing confidence in the system used to measure the process.

November 1, 2016

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing