Measurement

Test & Inspection

Why ensuring quality calibration of your precision measurement equipment is critical.

Read More

Measurement

Gaging Evolves For Precision, Productivity, Ergonomics & More

Gage design is continually being enhanced and refined.

December 6, 2021

Quality Headline

Renishaw Announces Expanded CMM Software Offering with New Verisurf Agreement in North America

December 1, 2021

Quality Headline

NIST Requests Information to Help Guide Emerging Technologies

November 30, 2021

Column | Hill Cox

Other Dimensions: DIY Gage Calibration: A Primer for Management

One of the hardest parts of doing your own gage calibration is having the right personnel to do the work.

November 15, 2021

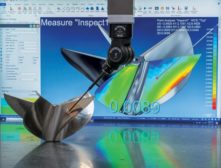

How 3D Scanning Solution Boost Quality Gains and Productivity

The key to being successful with automated measuring solutions is to simplify the deployment.

November 9, 2021

The Ins and Outs of Portable CMMs

Learn how a portable CMM works, and why it differs from other, similar tools.

November 8, 2021

Quality Headline

New Technology, Innovative Exhibits, Education, Networking Featured at 4th Biennial Quality Show

November 2, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing