Test & Inspection

Case Study

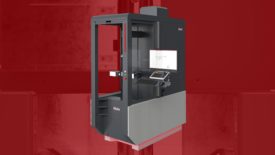

With an x-ray inspection machine, the company is able to guarantee the quality of the castings faster and more comprehensively.

Read More

Test & Inspection

Is it Possible to Measure Shaft, Form and Gear with an All-In-One Machine?

Do more with less — minimizing downtime for production workpiece measurements.

May 30, 2022

Test & Inspection

Measurement And Inspection Standards

As technology continues to evolve, it will take a lot of work from the standards community to help the industry keep pace with news tools for new manufacturing methods.

May 1, 2022

Test & Inspection

The Journey to Creating an Inspection Standard

The scope of inspection is so vast that no one wanted to exclude a topic, but we also did not want a standard so detailed that it was not user friendly.

May 1, 2022

Test & Inspection

Eddy Current Inspection of In-Service Aircraft Structure

Eddy current inspections are particularly sensitive to crack, corrosion, and other conductivity changes within electrically conductive alloys.

April 1, 2022

Test & Inspection

Shining A Light On Color Quality Control

Monitoring color during the entire production process can help manufacturers identify color drifts before they become a problem.

March 8, 2022

Test & Inspection

Aerospace Companies Flying High With 3D Laser Trackers

Portable metrology tools like 3D laser trackers are efficient solutions that can be implemented into aerospace workflows.

March 8, 2022

Case Study

How A Custom Crusher Used Precise Motion Data To Open New Manufacturing Possibilities

The problem wasn't whether the client could make the parts; it was whether the client could test samples in a rapid, cost-efficient, productive way.

February 15, 2022

Test & Inspection

The Shrinking Pixel

What motivates smaller pixels? It's mainly cost, which is directly tied to image sensor size.

February 15, 2022

Test & Inspection

How Collaborative Is Your Manufacturing Application?

The design and operation of the manufacturing application will determine how and how often the human and robot will collaborate.

February 15, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing