Test & Inspection

NDT | Certification

The need to formalize the qualification of NDT practitioners gradually became apparent.

Read More

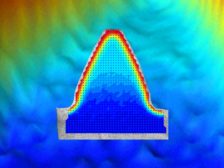

NDT | Ultrasonics

The Critical Role of Ultrasound in Advance Additive Manufacturing for Industrial Applications

Inspection plays a critical role during all phases of product development and implementation, making UT methods an enabling technology for new AM applications.

October 15, 2021

Column | Hill Cox

Other Dimensions: Settling Measurement Disputes

Not all parties to a dispute understand the importance of uncertainty budgets.

October 8, 2021

Test & Inspection

Digital Technologies in Hardness Testing

Modern computer control of hardness testers has advanced far beyond making a single line of indents.

October 1, 2021

Column | Hill Cox

Other Dimensions: No Quote!

When you're fooling around with millionths of an inch, it doesn't take much to miss the target.

September 8, 2021

Test & Inspection

Modular Tooling Keeps On Truckin’

This technology is here to stay.

September 1, 2021

Test & Inspection

How the Pandemic and Quality 4.0 are Changing Testing and Inspection

To discuss trends in testing and inspection, we must first discuss the impact of Covid-19.

August 8, 2021

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2024. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing