Software

A document control system opens up the opportunity for improvement in other areas of your business.

Read More

Document Change Control Management

Control the lifecycle of all changes within a QMS system.

December 1, 2016

Gage Repeatability and Reliability: Ensuring Accurate Test Results for Measurement Systems

When designing a GR&R study it is important to select a range of materials that is representative of what the system will be used for.

November 1, 2016

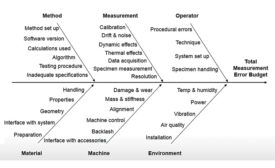

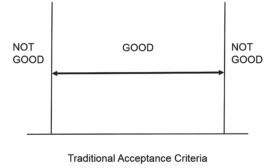

Gage R&R: The Key to Reducing Measurement Variation

A critical part of the journey toward reducing variation is developing confidence in the system used to measure the process.

November 1, 2016

Reverse Engineering Continues to Expand its Role in Industry

Reverse engineering parts and systems enable aircraft to keep flying or machines to keep running.

October 1, 2016

INDUSTRY HEADLINE

InspectionXpert Corporation Announces QualityXpert Beta

September 27, 2016

Stepping up to the Factory of the Future

Predictive simulation is underpinning the factories of the future through immersive visualization of the vast amount of data from Industry 4.0 components and machines.

September 1, 2016

Tolerancing Standards: A Comparison

As we consider the possibility that products can be manufactured anywhere in the world, we must also think about the specifics of the standard we use to describe the product requirements.

August 1, 2016

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing