Vision & Sensors

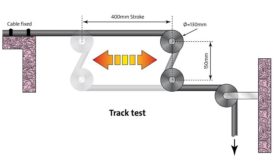

All cables should be fully tested to check they have the correct point-to-point connections.

Read More

Interfaces for Machine Vision

Both consumer and dedicated interfaces are used across many machine vision applications.

May 5, 2020

LED Light Pulses Enter the Nano Realm to Keep Pace with High-Speed Imaging

A competent vision designer can optimize image capture at extremely high speeds.

May 4, 2020

Machine Vision Software: What’s “Under the Hood”

Let’s ensure that your machine vision applications all will be successful and reliable now and in the future.

May 4, 2020

Smart 3D Robot Vision: The Science of Seamless System Integration

Learn how 3D smart sensors can be tightly integrated with robots to achieve a number of dynamic manufacturing processes.

May 4, 2020

Vision & Sensors Headline

Boulder Imaging Announces Leadership Additions, Team Expansion

April 7, 2020

Sponsored Content

How to create an intelligent industrial camera without prior knowledge

April 7, 2020

Quality in Automation > Automation 101

Automation for Beginners and Experts

Whether a newcomer or grizzled expert, it never hurts to brush up on the fundamentals of automation and robotics.

April 6, 2020

Quality in Automation > Robotics 101

The Details of Vision Guided Robotics

Vision guided robotics today encompasses all the technologies needed to recognize, process and handle objects based upon visual data.

April 6, 2020

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing