Vision & Sensors

Quality Headline

Canon Medical Completes Acquisition of Toshiba’s Imaging Systems Division

October 7, 2019

Vision & Sensors Headline

Machine Vision Lighting Market to Nearly Double by 2025

September 9, 2019

Vision & Sensors Headline

VDMA OPC Machine Vision initiative: Making Machine Vision Ready for Industry 4.0

September 2, 2019

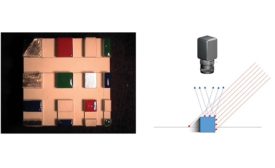

Illumination: The Third Pillar of Imaging System Design

Illumination is an often-overlooked yet crucial aspect of vision.

September 1, 2019

How to Choose a Vision Lighting Technique

5 common vision lighting techniques and 5 critical questions to ask.

September 1, 2019

Machine Vision Trends

A look at the most talked-about machine vision technologies, their practical uses and limitations, and which will have a long-lasting impact on your current and fixture applications.

September 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing