Vision & Sensors

Vision & Sensors Headline

Vision & Sensors Headline

Applied Vision Completes Latest Headquarters Expansion

July 10, 2019

Self-learning Intelligence for Object Recognition

More and more, advanced artificial intelligence technologies are being incorporated into machine vision systems.

July 1, 2019

Choosing Sensors for your CMM

The goal of part inspection is to get results you can trust.

July 1, 2019

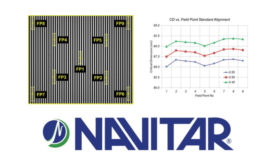

Sponsored Content

Improvements in Machine Vision Accuracy with Lens-Sensor Active Alignment

July 1, 2019

The Future of Machine Vision Imaging Systems

Beginning with the AIS's camera link standard, the industrial camera portion of the imaging system was standardized.

July 1, 2019

How Machine Vision Cables Impact Machine Vision Performance

Choosing high quality cables is your best approach for long-term productivity and consistent imaging data.

July 1, 2019

Quality Headline

Analysis of Global Machine Vision Equipment Market, Forecast to 2022

June 25, 2019

Quality Headline

Exact Metrology Helps Create Red Stockings Pavilion Sculptures

June 25, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing