Vision & Sensors

Quality Headline

Dorsey Metrology Acquires Optical Comparator, Vision System Product Lines From S-T Industries

January 30, 2019

QUALITY WEB EXCLUSIVE

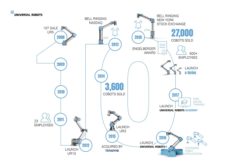

Universal Robots Celebrates 10 Year Anniversary of Selling the World’s First Commercially Viable Collaborative Robot

Universal Robots marks a decade of pioneering collaborative robots, now the fastest-growing segment of industrial automation.

January 3, 2019

Understand Tradeoffs to Maximize Lens Performance

The machine vision system is only as good as its lens.

January 1, 2019

Simple Steps to VGR Implementation

Vision technology is constantly being updated, especially where speed and resolution are concerned.

January 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing