Vision & Sensors

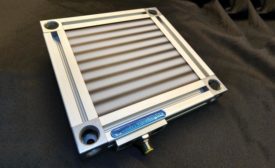

Patterned Area Lighting Simplifies Imaging of Reflective and Transparent Surfaces

The goal of PAL lighting is to enhance diffiult-to-image flaws so machine vision software can evaluate them.

March 1, 2019

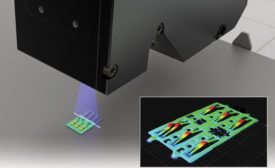

Designing a Better Sensor for Small Parts Inspection

Smart technology advancements are at the heart of today's movement toward better sensor design.

March 1, 2019

Can You Save Time and Money by Automating your Quality Processes?

Whether you are looking at industrial robots or cobots, automation can be a great solution.

March 1, 2019

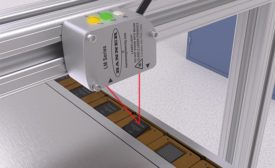

How to Choose a Precision Measurement Sensor: Key Considerations

In precise part inspections, a reliable solution is a must.

March 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing