Home » Keywords: » management systems

Items Tagged with 'management systems'

ARTICLES

Lean with Lazarus | Ian R. Lazarus

System 1 is satisfied to draw conclusions with limited data, and more often than not, System 2 never bothers to get involved;

Read More

Quality 101

Building Blocks to Improve Organizational Culture

Lay out a road map to achieve organizational excellence and build a culture around it.

May 30, 2023

Why Adopt Risk-Based Thinking?

Automated risk management tools can help manufacturers incorporate risk-based thinking into their processes.

June 3, 2021

Speaking of Quality | Tash Baksh

Facing Change

The best way to approach change is together.

March 5, 2021

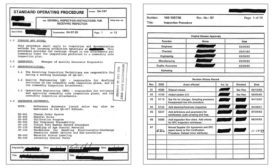

Lean ISO Management Systems: How to Create Lean Procedures

The objective is to eliminate or minimize waste within the process without impacting the outcomes.

May 1, 2020

All Together Now: The Benefits of Integrating Management Systems

With the transition from OHSAS 18001 to ISO 45001, it’s easier than ever. But how do you start, and what should you look out for?

August 8, 2019

The Principles of Quality Management

Learn more about these quality basics in order to improve your organization.

April 2, 2019

QUALITY WEB EXCLUSIVE

All About 5S: Definitions and Benefits For Today’s Manufacturers

January 13, 2019

The Future of Management Systems

Let’s look at seven global megatrends that will affect organizations in the coming years.

September 1, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing