Home » coordinate measurement machine (CMM)

Articles Tagged with ''coordinate measurement machine (CMM)''

Automotive

Inside the Expanding Applications of Vision Measurement Systems in Automotive Manufacturing

Here are the key advantages of vision systems for automotive manufacturers.

May 8, 2024

Measurement

How IoT Integration Enhances Quality and Speed, Part 2

IoT’s real-time analytics and in-process control are making operations more precise and products more reliable.

May 2, 2024

Measurement

Precision Trends in Metrology, Part 1

The integration of 3D CAD models and advanced software algorithms are setting new standards for accuracy and efficiency in manufacturing.

May 2, 2024

CMS Column | Justin Novak

How Has Metrology Changed in the Past 40 Years?

A lot has happened since 1984, and we're just getting started.

April 3, 2024

Measurement

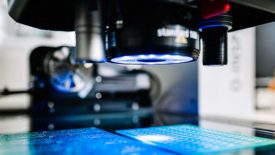

Metrology and Microscopy for Electronics Quality Assurance — in One Machine?

Compliance can often only be achieved through both metrology and microscopy tools.

March 5, 2024

Quality Headline

Fowler High Precision Appointed Exclusive U.S. Distributor for Aberlink’s Shop Floor, Lab Grade CMM Equipment

March 4, 2024

Case Study

Unlocking Efficiency in Education

Inspection Arsenal fixturing transforms student part inspection at Van Buren Tech in Lawrence, MI.

March 1, 2024

Quality 101

The Next Dimension of Precision: Integrating Rotary Tables into Coordinate Measuring Systems

The accuracy and reliability of CMMs and PCMMs are foundational to quality.

February 16, 2024

Test & Inspection

When Part Gaging is a Bottleneck

Automatic manual gauging improves process control, yield, and capacity.

January 26, 2024

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing