Home » coordinate measurement machine (CMM)

Articles Tagged with ''coordinate measurement machine (CMM)''

Whether you chose an optical, tactile, or hybrid shaft gage will depend on your unique needs.

Read More

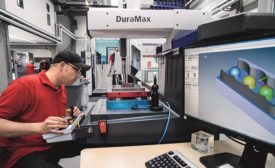

Improving Your Manufacturing Productivity and Quality with CMM Networking and Automation

Consider automating and moving your CMMs to the shop floor.

January 1, 2020

Fully Leveraging Machine Uptime

Offset measurements away from the machine tool boost manufacturing efficiency.

November 5, 2019

Shaft Measurement: What is the Best Tool for the Job?

Shaft measurement can be performed with a variety of metrology tools, from handheld devices to high-end coordinate measuring machines.

November 1, 2019

Achieving the Ideal Measuring Room with the Right Accessories

It’s critical to optimize your measurement machines and quality program with the right tools for your application.

September 1, 2019

Increasing Productivity with CMM Automation

Discover how shop floor equipment can simplify your measurement process.

August 1, 2019

Choosing Sensors for your CMM

The goal of part inspection is to get results you can trust.

July 1, 2019

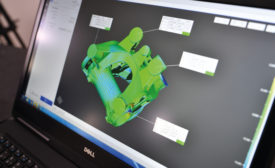

3D Scanning with Metrology

Metrology applications can benefit from the speed and data available from 3D scanning.

July 1, 2019

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing