Home » coordinate measurement machine (CMM)

Articles Tagged with ''coordinate measurement machine (CMM)''

Measurement

When are non-contact structured light 3D scanners better suited than touch CMMs?

Read More

Case Study

Miltera Achieves Success with ZEISS Industrial Quality Solutions

Miltera has built up a reputation as a specialist in producing everything from racecar parts to mold components, consumer electronics, turbine compressors and turbochargers for the aerospace industry.

August 16, 2022

Software & Analysis

Inspection Software Must Itself be Inspected

Software decreases the time to identify and eliminate quality risks, reuces risk-related expenses, improves compliance capacity, and optimizes labor.

August 1, 2022

Today’s CMMs Are Known for Adaptability, Ease of Use

As the skills gap continues to impact the manufacturing field, skilled CMM users and programmers are harder to come by. In response, CMM companies have built the tools to be easier to operate and program.

July 8, 2022

Minimize Supply Chain Delays With Robust Production Lines

Maximize metrology and minimize bottlenecks to keep your production lines running at full capacity.

June 6, 2022

Test & Inspection

Is it Possible to Measure Shaft, Form and Gear with an All-In-One Machine?

Do more with less — minimizing downtime for production workpiece measurements.

May 30, 2022

Quality Headline

Hexagon’s Manufacturing Intelligence Opens Canadian Calibration Laboratory in Oakville, ON

May 2, 2022

Why model-based Measurement Helps Manufacturers Improve Quality

Improvements in CMM equipment and developments in model-based software solutions have also helped make the technology more accessible.

March 23, 2022

Quality 101

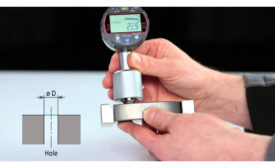

5 Things To Consider When Evaluating Shop-floor CMMs

As your manufacturing processes change over time, you need your quality program to keep up.

March 8, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing