Home » coordinate measurement machine (CMM)

Articles Tagged with ''coordinate measurement machine (CMM)''

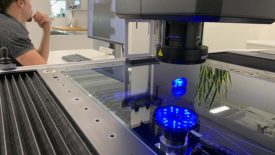

High- Speed Measurement

Quality assurance performed at the site of production can identify and possibly even avoid manufacturing errors.

Read More

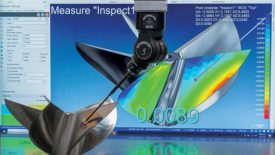

Software & Analysis

Advanced Quality Inspection Software Offers Many Benefits, But Adoption Lags

From addressing labor shortages, to reducing human error, the future looks bright for quality inspection software.

May 9, 2023

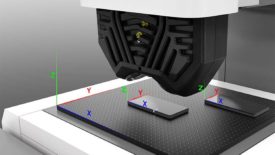

Measurement

How to Measure the Intricate Components of Electrical Connectors

Quality assurance is critical for manufacturing electrical connectors.

March 30, 2023

Vision & Sensors | Inspection

Exploring Integrated Optical Inspection Systems

For noncontact surface characterization of manufactured materials.

March 6, 2023

Test & Inspection

Inspection Fixturing – Not A Question Of IF!

Whether you've been tasked with designing fixtures or sourcing them for your company, there are several details to consider.

February 8, 2023

Software & Analysis

Choosing the Right Measurement and Inspection Software

January 5, 2023

The Spending Forecast is Here

The 22nd Annual Quality Spending Survey Results

Concerns about Covid-19 are down, but inflation worries are up.

December 29, 2022

Vision & Sensors | Automation

Metrology Automation Finally Arrives

The smart start to metrology.

December 7, 2022

Test & Inspection

The Most Common Styli Used Today

Let's discuss the most common styli used today.

November 30, 2022

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing