Home » coordinate measurement machine (CMM)

Articles Tagged with ''coordinate measurement machine (CMM)''

The need to optimize throughput is a common denominator across industry lines.

Read More

Air Gaging in a Quality Management System

The most important consideration is the assurance of accuracy through calibration.

September 1, 2017

Controlling the Accuracy of a Shop Floor CMM

Understanding the influence of temperature on your CMM.

September 1, 2017

INDUSTRY HEADLINES

Perceptron Awarded Large Helix 3D Scanning Sensor Order in China

August 23, 2017

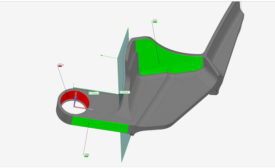

First Article Inspection with 3D Scanning

A growing number of companies are including this technology in their first article inspection procedures.

April 1, 2017

Navigating the New World of CMMs

How to select a CMM for your unique application.

February 1, 2017

Metrology Looks Towards Automation

Metrology and inspection solutions aim to stay in-line with factory automation.

December 1, 2016

Boldly Re-engineered CMMs Take Throughput Seriously

Exploring trends and developments in today’s inspection equipment technology.

December 1, 2016

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing