Home » coordinate measurement machine (CMM)

Articles Tagged with ''coordinate measurement machine (CMM)''

CASE STUDY

Automated Car Body Measurement

Fixturing provides a solution for a VW automotive application.

October 1, 2015

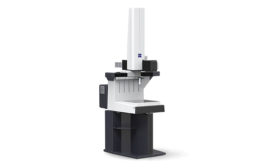

Expand Your CMM’s Capabilities

Moving from tactile and scanning systems to newer optical and laser sensor technology increases the productivity of your CMM.

August 5, 2015

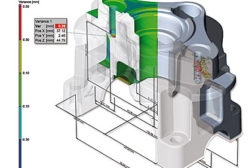

Industrial X-ray CT: Quality Control from the Lab to the Production Floor

Recent speed and accuracy developments have allowed the migration of CT technology.

June 9, 2015

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing