Home » coordinate measurement machine (CMM)

Articles Tagged with ''coordinate measurement machine (CMM)''

While manufacturers have applied model-based definition to product definition for some time, they have only recently applied it as a quality assurance process.

Read More

Mitutoyo Delivers Greater Productivity and Accuracy

Automotive supplier Dynamic Manufacturing benefits from CNC CMM.

March 2, 2015

INDUSTRY HEADLINE

Hexagon Metrology Recognized by Leading University for Contribution

February 10, 2015

INDUSTRY HEADLINE

Perceptron Inc. Acquires CMM Designer, Manufacturer COORD3, CMM Software Developer

February 3, 2015

Measurement

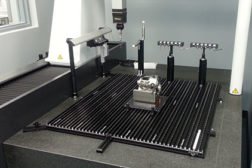

Measurement Accuracy in Coordinate Metrology

Learn more about influencing factors, determination and optimization

April 1, 2014

Customer-centered Focus Results in Integrated Innovations

CMM manufactures study customers to enhance user experience.

February 3, 2014

Frost & Sullivan: Adoption of Large-scale CMMs and Laser Trackers to Drive Demand from the Aerospace Industry

Applications involving inspection of aerostructures and aeroengines to boost demand for customized metrology solutions

January 16, 2014

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing