Home » coordinate measurement machine (CMM)

Articles Tagged with ''coordinate measurement machine (CMM)''

Advancements in motors and sensors improve CMM surface measurement capabilities.

Read More

INDUSTRY HEADLINE

Metrologic Group and Stäubli Robotics Introduce Absolute Coordinate Measuring Robot

April 16, 2018

INDUSTRY HEADLINE

HMS Industries Inc. Selects Rize One 3D Printer to Build Functional Tooling for Production

March 15, 2018

INDUSTRY HEADLINE

Coordinate Metrology Society to Offer New Certification Programs for Measurement Professionals

March 6, 2018

INDUSTRY HEADLINE

ASF Metrology to Acquire Nikon Metrology's Coordinate Measuring Machines Business

February 8, 2018

INDUSTRY HEADLINE

2018 Call for Papers Opens for the Coordinate Metrology Society Conference (CMSC)

December 12, 2017

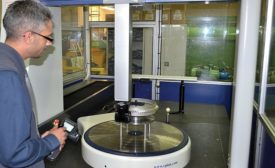

Accurate and Repeatable Measurement

Using a rotary table on a CMM will improve process efficiency and productivity by reducing setup and process times.

October 24, 2017

INDUSTRY HEADLINE

New Metrology Program at Fullerton College to Integrate Romer Absolute Arms and CMMs from Hexagon Manufacturing Intelligence

October 18, 2017

Stay in the know with Quality’s comprehensive coverage of

the manufacturing and metrology industries.

eNewsletter | Website | eMagazine

JOIN TODAY!Copyright ©2025. All Rights Reserved BNP Media.

Design, CMS, Hosting & Web Development :: ePublishing